How traditional problem-solving methodologies can be utilized in the digital era

Introduction

This article seeks to spark discussion, stimulate the flow of ideas, and propose strategies which enterprises can capitalize from two different methodologies: traditional process improvement methodologies (TPIM), such as Lean, Just-in-time (JIT), Toyota Production System (TPS), Total Quality Management (TQM), and Digital Transformation (DX). These seamlessly opposing powerhouses can drive true transformation inside organization if properly combined.

History/Background

Digital Transformation (DX) or Digitization is a set of actions taken by an organization, or any entity for that matter, to shift the nature of their business totally or partially from Analog — physical, in-person — to Digital — through a software or application.

Companies go through a journey of incorporating digital solutions into business processes to provide more value to their customers and become more competitive in the market they operate. The digital endeavor not only seeks to replace current processes but also aims at streamlining new ones to deliver products and services with a certain aim (eg. higher quality, less delivery time, higher customer satisfaction, etc.). Digital Transformation (DX) has been in the forefront of organizations for the last few years and has created a new trend in both Services and Manufacturing, accelerated by the latest advancements in technology, such as: Cloud Computing, Industry 4.0, Augmented Reality (AR), Virtual Reality (VR), or AI. This and prior generations of Technology promise to bring better customer satisfaction and data-enabled insights, limit human error, and increase speed. Arguably, this warped focus on goals and metrics creates another layer of challenge, but that’s for another occasion.

Opposed to these benefits, DX has been adding an irrational sense of urgency, most of the times leading to the digitization of wastes, mandating the organization to remedy new problems, increasing their time to market, their costs, increasing frustration among employees and client, diminishing morale.

Technology is unavoidable, but it’s not miraculous. It does not mean is a “fire and forget” endeavor. It should not be followed blindly, it must materialize a “true need” identified, solidified, and scrutinized ideally by a market opportunity or gaps. That way, it delivers a solution with less cost and maximum return on investment.

Technology must follow processes, not the other way around.

Implementation of a digital solution must be the product of intense knowledge of current processes, combined with a solid strategic view of the future.

On the other hand, traditional process improvement methodologies have been losing space and getting deprioritized. Once the spearhead of transformational efforts, these (TPIM for short) are now seen as formalities, organizational bureaucracy, or a misunderstood diligence.

Let’s remember that their birthplace was a post-WW2 Japan, having to reinvent society and economy to minimally survive, with scarce natural resources and labor. Japanese companies, such as Toyota, started looking inwards, targeting wastes (Muda) with the purpose to reduce operational costs and deliver higher quality products. The legacy of that, the work of many others like Deming, Shewhart, and Juran, is what we know as Lean, a set of steps, norms, and, most of all, a toolkit to logical thinking and problem solving.

DX and TPIM can each flagship vital transformation, but how about both together? Coupling LSS with Digitization can be challenging but it is a great course of action to drive higher returns, long-lasting results, and more satisfied customers. The compounded journey utilizing both approaches will then become a Value Journey.

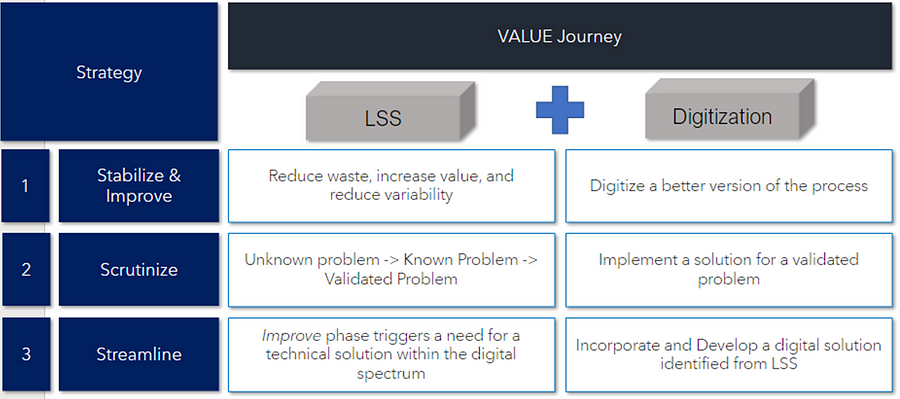

I propose 3 strategies to lessen conflict and increase momentum:

- Stabilize and Improve: Use of PDCA/DMAIC ahead of all digital work to hand over a more efficient, less wasteful, and higher-value version of the process and digitize it, avoiding “digitization of wastes”.

- Scrutinize: Utilize quality TDIM tools to validate assumptions, and deliver a robust problem statement, and root cause so that a potential problem becomes a real opportunity.

- Streamline: During the Improve phase of an LSS project, the goal is to formulate a set of potential solutions to remedy the problem: partially or entirely.

“If you don’t know where you are, you don’t know where you need to go.”

In most transformation journeys, the problem is unknown and undefined at the early stages. The natural and logical step is then to discover and frame this problem, and this step is where some of in successes might be rooted in. Problem discovery is the oxygen that the project should breathe, but is often bypassed, fast forwarded, or all together skipped, increasing confusion, scope creep, costs, and bottom-line chances of failure.

The basis of PDCA, for example, is to bring logical thinking to solve a specific problem. This problem is, at the beginning of the journey, unknown and undefined. A great part of Plan is (or should be) spent defining the problem and the root causing it. These steps are exhaustive and time-consuming, but they surely set the business to a higher chance of success. Defining the problem is not just cosmetic, it is a prerequisite to achieving an impactful, cost-effective, and sustainable solution. At a glance, Lean focuses on transforming work, and driving improvement by identifying and eliminating wastes in a process; Six Sigma focuses on the reduction of variability in the very process steps that add value and increase process performance based on customer’s specifications.

Digital Transformation

Digital Transformation (DX) or Digitization is a set of actions taken by an organization to shift the nature of their business from Analog — physical, in-person — to digital — Software, Cloud-based or applications. Companies go through a journey of integrating digital solutions into business processes to provide more value to their customers and to become more competitive in the market they operate. The digital endeavor not only seeks to replace current processes but also aims at streamlining new ones to deliver products and services. DX has been propelled by the latest generation of tech allowing companies to reimagine themselves from the standpoint of giving the customers what they need. The main types of technologies applied are Mobile Technology, IoT, Robotics, AI / Machine Learning, AR / VR, Big Data, Cloud-based solutions, or API-Based Integrations.

Another unexpected factor has played a huge part in accelerating an already fast change: the Pandemic. A positive side of this sad story is that DT initiatives have benefited from the forced distance created between people, imposing on businesses to operate digitally. With Covid, more and more companies have been engaging in Digital Transformation initiatives. According to a study from Digitalisation in Europe 2020: Evidence from the EIB Investment Survey(1), more than one-third of firms in Europe and the US expect the pandemic to have a permanent effect on the services or products they offer as well as on their supply chains.

It becomes apparent that companies around the globe are bringing Digitization to the core of their strategy. Quick research on the internet shows trend for Critical to Success Factors (CSFs):

- Design solutions for emerging customers based on their needs and desires

- Client in the epicenter of actions

- Customer obsession

- Communication of project status updates, streamlined processes, and prioritized investments

- Collaboration and continuous focus on goals and progress.

- Established KPIs and metrics that help prioritize innovations and changes

On the other hand, developing and implementing digital solutions do not come cheap. Estimates are that Worldwide Digital Transformation Investments will reach $1.8 Trillion in 2022(2) (+ 17.6% over 2021). Other studies(2) suggest that these investments are taking large enterprises especially at least twice as long and costing twice as much as they originally anticipated.

The speed with which things are happening has placed a distorted sense of urgency in businesses clouding the view of the real objective. Some companies were naturally migrating to Digital before it all became the forefront of transformational projects; some others are exhaling desperation in catching up with it. In this digital “gold rush”, old problems were unearthed. Most digital projects suffer from Scope Creep, Vague Objectives, Insufficient or No Support from Upper Management, and Low connection to the company’s objectives. The unrealistic sense of urgency is leading businesses to deliver platforms and applications to the opposite of driving value. The same happened to Lean and Six Sigma in the past, most companies failed and still fail to this day to drive positive and sustained results. A blind aim, a need to “show”, sometimes masked as “efficiency”. The necessity has been sometimes “to look” digital more than “to be” digital; these failed solutions become a problem on their own later and the consequences are dire:

- Digital products that are not user friendly

- Platforms with no clear objective

- Platforms that don’t address the real problem

In most of these cases, no sufficient effort (time, budget, staff) is applied to answering the most basic primary questions of all: what is the problem that needs to be solved? It seems far worse to embark on a digital journey with no clear problem to solve than spend proper time validating assumptions.

This is old knowledge, the Greek philosopher Yogi Berra said: “If you don’t know where you are going, you’ll end up someplace else”. It becomes evident that a well-rounded problem leads to a more successful solution. The use of cutting-edge technologies without delivering value to customers only leads to financial and strategic losses. Similarly, a true transformation cannot be accomplished without challenging the status quo and getting comfortable with failures. Placing timelines ahead of quality is a dangerous gamble.

How can companies tie up these two methodologies?

So, DX and LSS can each flagship vital transformation, but how about both together? Coupling LSS with Digitization can be challenging but it is a great course of action to drive higher returns, long-lasting results, and more satisfied customers. The compounded journey utilizing both approaches will then become a Value Journey. There can be 3 ways, or strategies, that can be applied:

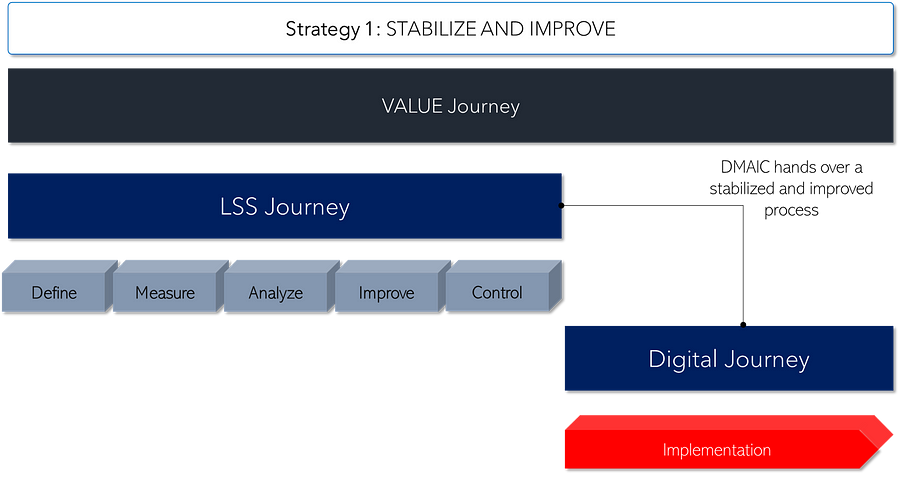

[1] Stabilize and Improve

The core of this strategy is the execution of LSS’s full-blown DMAIC ahead of all digital work to hand over a more efficient, less wasteful, and higher-value version of the process and digitize it, avoiding “digitization of wastes”.

One example to illustrate this is the process for the replacement of a driver’s license in case of damaged, stolen, or lost. Today that process happens in person and managers quickly come up with the idea of digitizing the service, envisioning a platform to replace the old method. They then get the necessary approvals, budget, and team. They go through an RFI, RFP, and all steps that lead to hiring a competent third-party vendor to implement the solution. Even though this might be a viable approach, it does not guarantee the expected results. For example, the process now takes 22 days on average instead of 15 days. What went wrong? What could possibly have gone wrong? The managers may ask. It could be that wait times increased due to electronic backlog, cycle times spiked because employees were not poorly trained in the new platform, or poor communication between employees — Out of a multitude of reasons, there is a high chance of something digitization failed to address.

A better approach to this case would be to undertake an LSS journey before anything else so the process could be stabilized, wastes eliminated, risks assessed, and performance improved.

[2] Scrutinize

Utilize LSSs tools to validate assumptions, and deliver a problem statement, and root cause so that a potential problem, becomes a real opportunity.

“If I had an hour to solve a problem, I’d spend 55 minutes thinking about the problem and five minutes thinking about solutions.” — A. Einstein

The mother premise for an improvement project using LSS is to find out what the problem is. LSS functions by assuming the problem is unknown at the beginning. Hints, fragments, and opinions will naturally exist but, the process owners and subject matter experts must be incentivized to adopt a “blank slate” mentality leaving preconceptions, beliefs, and half-truths at the door.

Often, we come across a group of individuals with extensive knowledge and experience in the business and despite being an asset to the work, the overreliance on “absolute truths”, assumptions, and perceptions about the process is dangerous. It is natural to think, “I already know what the problem is” or “I know what their client needs” — but that’s not a healthy mindset for true problem-solving, especially in the LSS realm.

LSS dedicates time and effort to holistically hearing customers and crafting and validating the problem statement, the root causing it, and then “solutionizing”. It advocates a certain degree of skepticism even toward the process. Lean Six Sigma have the customer as the centerpiece of their work.

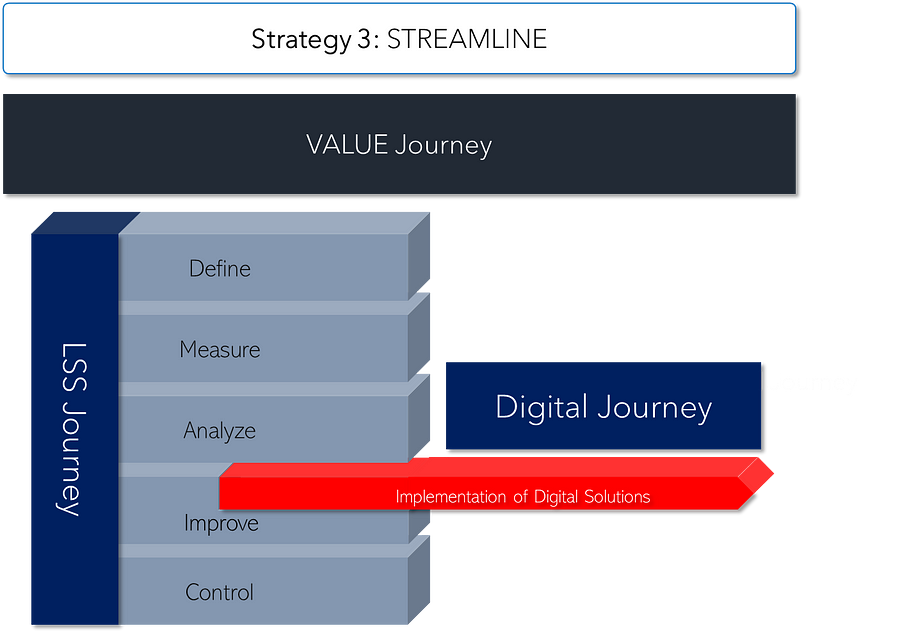

[3] Streamline

During the Improve phase of an LSS project, the goal is to formulate a set of potential solutions to remedy the problem: partially or entirely. Key activities of this phase are ideation, prioritization, experimentation, and implementation. It is at the “Improve” phase where we normally see a breakdown of the classes of solutions based on complexity and impact, or their nature.

The solutions are generally grouped into non-technical and technical. The first cluster concentrates on training, new procedures, new practices, incentives, policy changes, and reporting/governance are examples of non-technical ones. In the technical realm reside new tools, new methods, automation, new platforms, and applications.

For the second group of solutions, an implementation journey will start derived from the LSS journey that materialized previously. Some of them will be associated with Technology, like an Automation of repetitive tasks or Cloud servicing for faster and more secure service. This point of the project is crucial as LSS hands over the reins to a Digital Solution Implementation journey, which now has a higher chance of success.

Conclusion

Digitization is important and almost unavoidable. Problems arise when there is a lack of preparation and planning. In this digital “gold rush”, old problems were unearthed. Most digital projects suffer from Scope Creep, Vague Objectives, Insufficient or No Support from Upper Management, and Low connection to the company’s objectives. These will lead the company back to old problems if not newer ones, mandating it to spend another round of capital.

The degree of digital transformation that the organization goes through seems to factor in a multitude of information, such as its mission and multi-year planning, current and future necessities of the market, industry under which the organization operates, budget for transformation projects, and maturity of processes.

LSS is still current and important to drive operational competitiveness. Even before the pre-conception of a process improvement endeavour, selecting and prioritizing projects that will increase the chances to bring the desired outcomes.

LSS and DX are not competing forces. On the contrary, they both have their functions. It would be like saying which is better, the hammer or the driller, when it’s clear that each has a specific function, time to use and outcome. It seems only natural to then think of both together, benefitting from each other. Creating strategies that include both LSS and DX is a smart way of getting closer to where companies want to be.

Sources:

(1) https://www.eib.org/en/publications/digitalisation-in-europe-2020-2021